Wastewater Treatment Plant

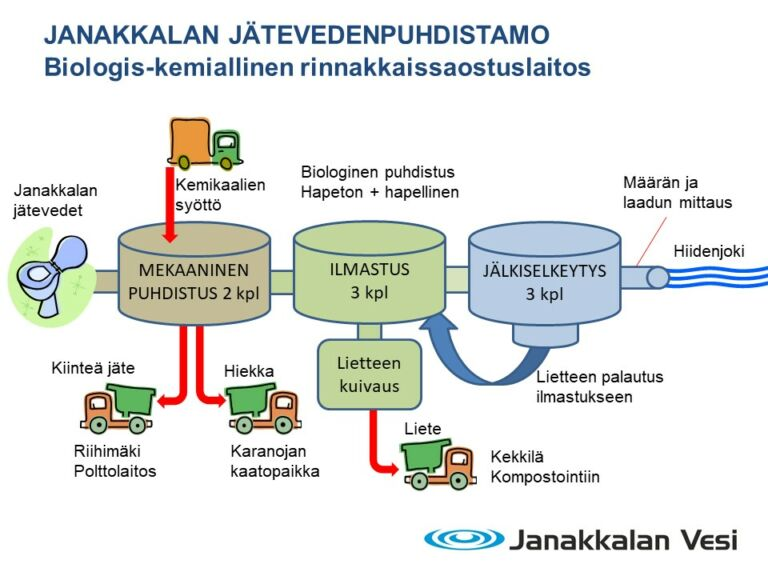

The Janakkala treatment plant is a biologically-chemical parallel sedimentation facility, where biological and chemical purification occur simultaneously.

Mechanical purification

The wastewater entering the treatment plant is lifted by screw pumps to the pre-treatment area, where solid non-soluble waste is first removed from the wastewater in a screening process. After this, the water passes through sand separation. Separated sand and screenings are washed and collected in their own containers awaiting final disposal. During pre-treatment, iron salts (ferric sulfate or ferric chloride) are added to the water to enhance phosphorus removal. The iron salts form larger particles with phosphorus that bind to the sludge present in the wastewater.

Aeration

To remove nitrogen from the wastewater, the organic nitrogen compounds in the wastewater must first be oxidized in an aeration process called nitrification to nitrate and nitrite. Subsequently, in an anaerobic zone, denitrifying bacteria are used to further convert the resulting nitrogen compounds to free nitrogen gas, which evaporates into the air.

From pre-treatment, the water is directed through pre-aeration to aeration basins where it is divided into three separate aeration lines, each initially having an anaerobic zone. After the anaerobic zone, the water is further aerated, allowing other bacteria to consume nutrients from the wastewater and convert them into a form that binds better to the sludge. In the aeration basins, a polymer is also added to improve the separation of the sludge in the clarification basins.

Post-clarification and sludge dewatering

After aeration, the wastewater is directed to clarification basins, where the sludge settles to the bottom of the basin and the purified water continues its journey from the surface of the basins through quality and quantity measurement back to nature.

The sludge remaining at the bottom of the clarification basins contains many bacteria necessary for purification, so it is pumped back into the aeration process. Excess sludge is removed from the aeration process to thickening basins, where the thickened sludge is dehydrated and sent for composting.

About the operation of the treatment plant

The treatment plant is equipped with backup power, so wastewater treatment continues even in the event of a power outage.

The operation of the treatment plant is monitored according to a mandatory monitoring program approved by the environmental authority. Mandatory monitoring samples are collected from incoming and outgoing wastewater using automatic samplers. The samples are analyzed by an external accredited laboratory that delivers the results directly to the supervising authority, the ELY Centre.

In the process, 99% of the organic load, 97% of phosphorus, and 90% of nitrogen can be removed from the wastewater.

A major single threat to the functioning of the purification process is the rainwater and stormwater that can enter the wastewater sewer, which diminishes the purification process. For this reason, separating rainwater and stormwater from wastewater at the properties is crucial for keeping our environment clean.